Checkout using your account

Checkout as a new customer

Creating an account has many benefits:

- See order and shipping status

- Track order history

- Check out faster

Monolith

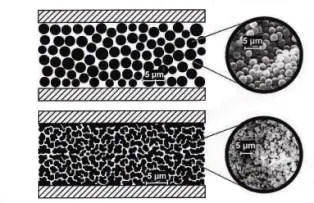

Monolithic phases consist of a single rod of highly porous material. Unlike other packaging materials, they have no particles. Monolithic materials can be made of either silica or an organic polymer and have two different pores. The macropores are very large (>1 µm) and allow the mobile phase to flow through the material. The mesopores are in the typical range of pore sizes of standard silica particles (100-300 Å) and are responsible for the highly efficient separation of the analytes.

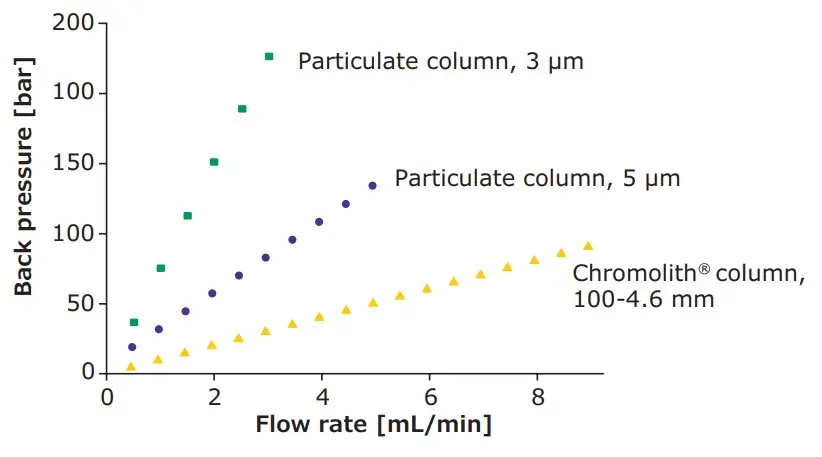

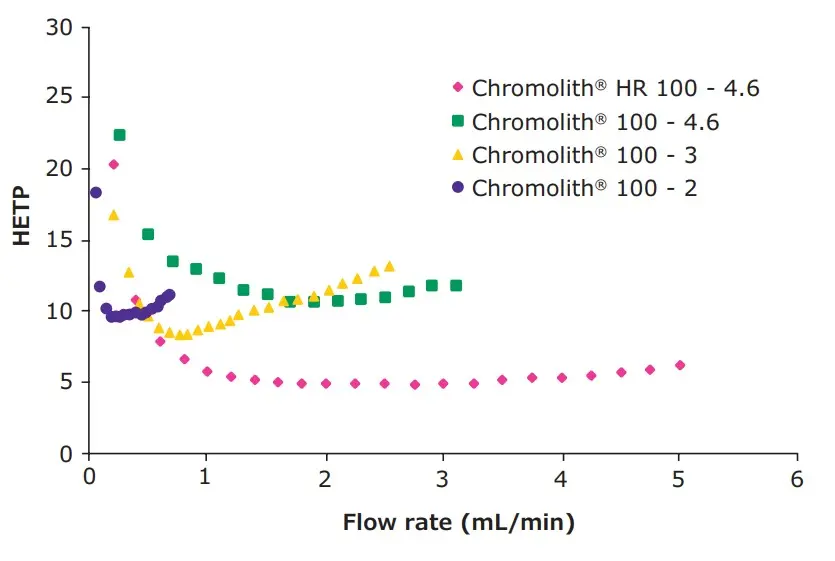

Due to the absence of individual particles, monolithic columns exhibit only low back pressures. In addition, the number of plates of these columns does not increase significantly when the flow rate is increased. On the one hand, this leads to the possibility of using high flow rates in order to shorten the analysis time. On the other hand, the columns last longer than HPLC or UHPLC columns due to the low back pressure.

Another advantage of monolithic columns is the high matrix tolerance. The structure of a monolithic column allows for more matrix in the sample. This means that time-consuming sample preparation is no longer necessary. This is particularly interesting for fast separations, where long sample preparation can reduce the sample throughput.

Write us a message and we will get back to you as soon as possible.