- 3% Discount on online orders

- Fast Delivery Times

- DIN ISO 9001:2015 Certified

- Manufacturer Expertise

- Contact Us

Checkout using your account

Checkout as a new customer

Creating an account has many benefits:

- See order and shipping status

- Track order history

- Check out faster

Syringes

Syringes are an indispensable tool in chromatography and play a central role in sample preparation and injection. They are used to introduce precise quantities of liquids or gases into the chromatographic system, which is crucial for the accuracy and reproducibility of the analyses.

Chromatography syringes are available in various designs and sizes to meet the different sample handling requirements. The most commonly used syringes are microsyringes, which are available in volumes ranging from microlitres to several millilitres. These syringes are characterised by their high precision and accuracy, which is particularly important when working with small sample volumes.

A key feature of chromatographic syringes is their material composition. High-quality syringes are often made of glass or special plastics that are chemically inert and resistant to the solvents and chemicals used. This prevents contamination and reactions that could impair sample quality.

The needles of the syringes are also of great importance. They are available in different diameters and lengths to meet different requirements. Thinner needles are suitable for injecting into small vials or columns, while thicker needles can be used for larger sample volumes. The tips of the needles can be pointed or rounded, depending on whether they are injected directly into the chromatographic system or into a vial.

Syringes with fixed needles are particularly useful for automated injection systems as they ensure consistent and reproducible injection. For manual injections, detachable needles offer more flexibility as they can be replaced if necessary.

Another important aspect is the tightness of the syringes. High-quality syringes have precisely manufactured plungers and seals that prevent leakage and enable even and controlled injection. This is particularly important when working with volatile or reactive substances.

Categories

Products

Technical Data

How do I choose the right syringe?

There are 5 steps to selecting the right syringe for an application. These include first selecting the syringe type, then determining the series based on the volume, with subsequent narrowing down based on volume, term and application, followed by determining the term of the syringe and finally selecting the needle type. The individual steps are listed below.

Step 1: Syringe type

A distinction can be made between microlitre syringes and gas-tight syringes.

Microlitre syringe:

- permanently installed syringe plunger (not interchangeable)

- for organic samples that do not precipitate or crystallise

Gas-tight syringe:

- Piston replaceable with PTFE tip

- Plunger can rub off and must then be replaced

- for volatile organic samples, water samples, viscous samples

Step 2: Determining the series by volume

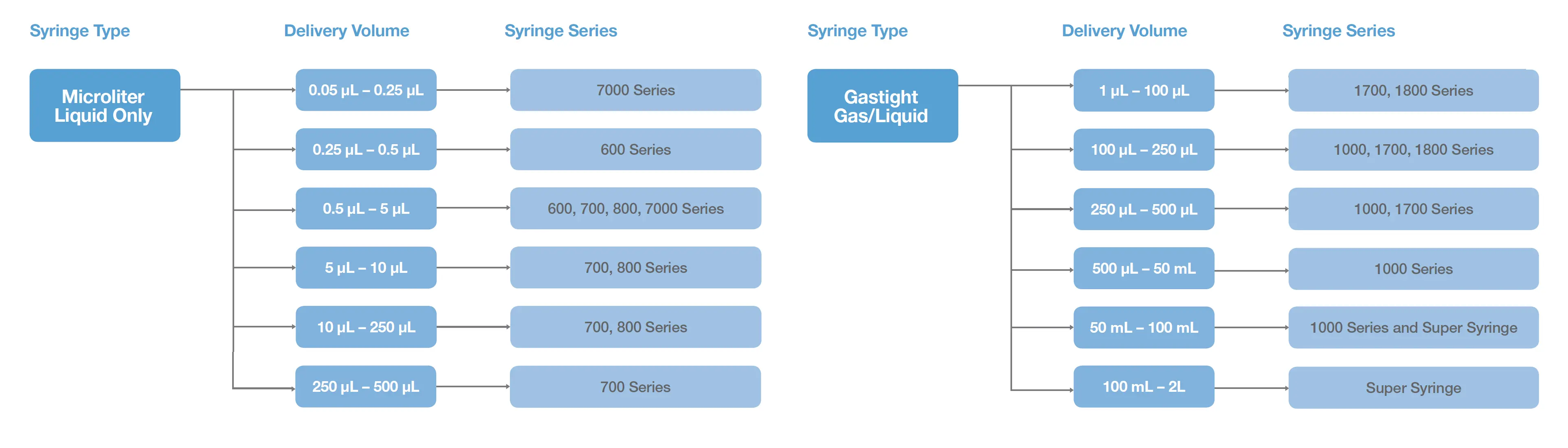

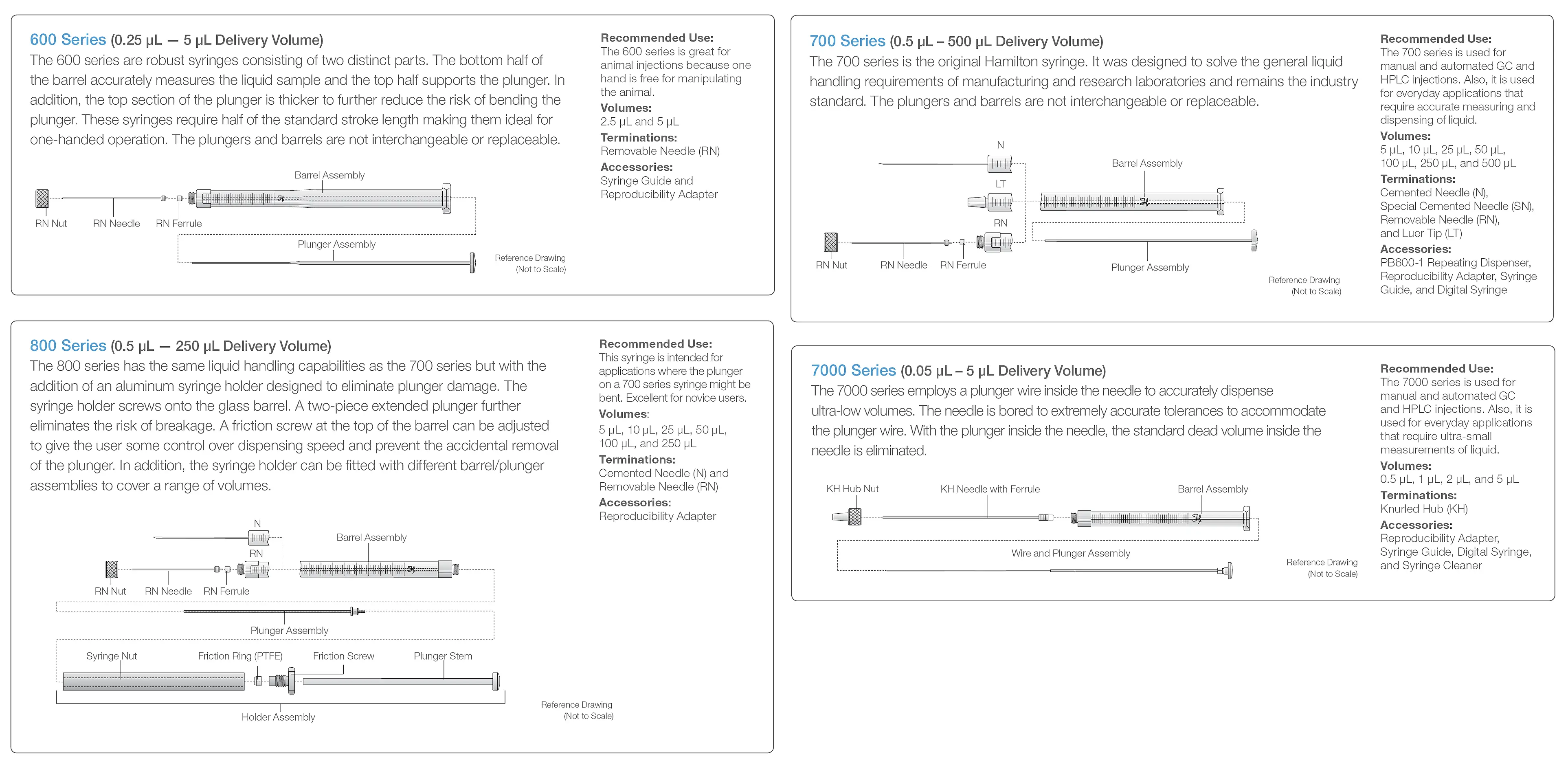

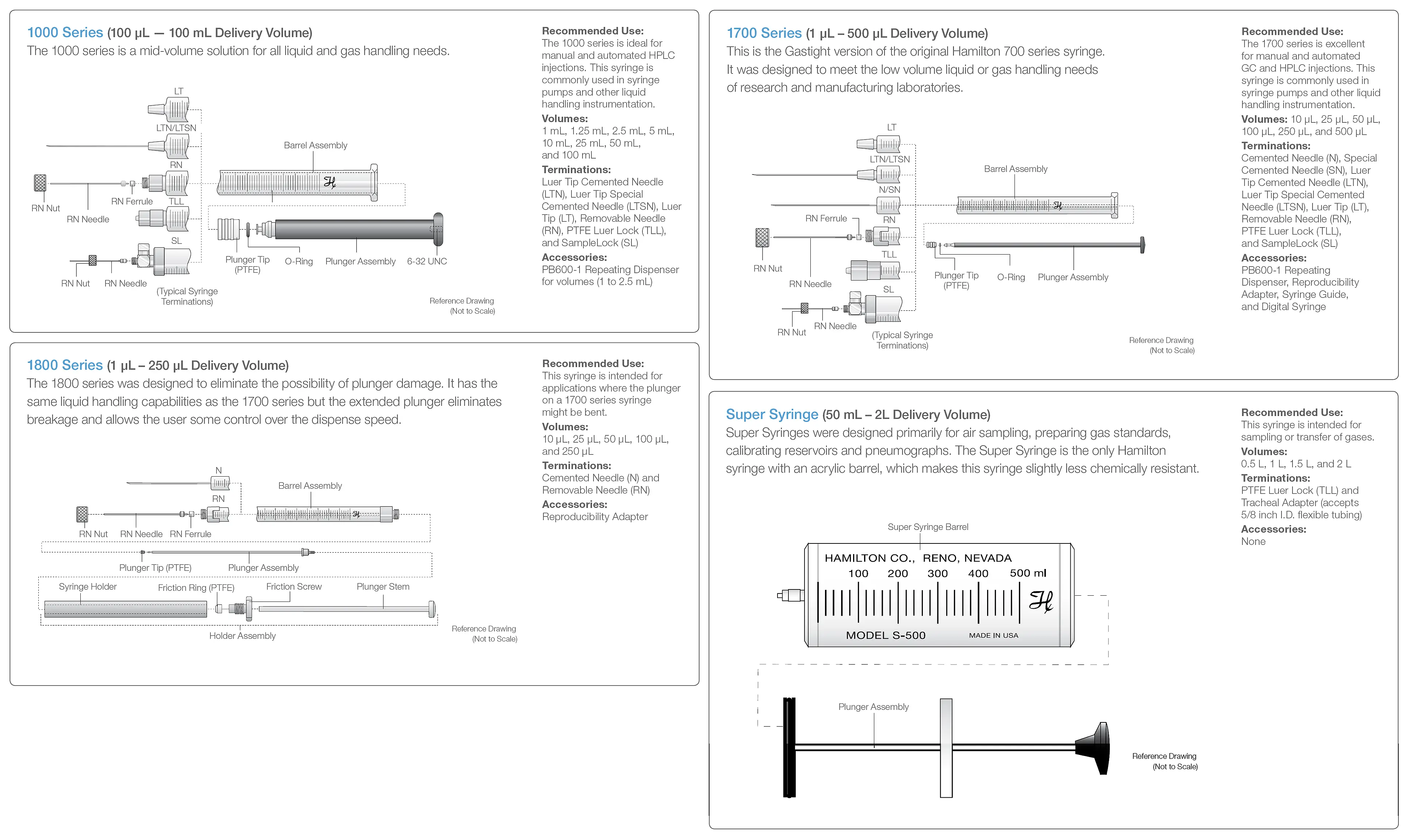

By selecting the syringe type, the choice of volume can be limited to certain series. The manufacturer Hamilton, for example, has a practical overview for this purpose.

Step 3: Selection of the most suitable series via volume, terminus and/or application

As can be seen in the overview for step 2, it is possible that several syringes in the series could be considered via the volume. Therefore, the desired volume, the terminus (needle connection) and the application must now be taken into account in step 3. If the volume and the terminus do not play a major role, the appropriate series can also be selected directly via the application. If only one series can be found for the desired volume, this step can be skipped.

Example volume:

- Microlitre syringe with a volume of 0.5 - 5 µL: the 600, 700, 800 and 7000 series are suitable for this purpose

- Desired volume 2 µL: Series 7000 has the option with 2 µL, Series 600, 700 and 800 do not → Series 7000 is the right choice

Example term:

- Decision cannot be made based on volume, as all available series offer this volume → Comparison of available terms

- the syringe should be a microlitre syringe with a volume of 5 µL, the 600, 700, 800 and 7000 series are suitable

- Termini should be LT (Luer Tip): Series 700 has this option → Series 700 is the right choice

Example application:

- The volume and the termini do not result in a decision because several series would fit → Decision on application

- the syringe should be a microlitre syringe with a volume of 5 µL and an RN (Removable Needle) termini, series 600, 700 and 800 are possible

- Syringe should be used for GC: Series 700 and 800 are suitable

- inexperienced users also work on the GC: 800 series is recommended

Microlitre syringes

(0.05 µL - 500 µL Delivery Volume)

This type of syringe is for use with liquids and incorporates a stainless steel plunger that is individually fitted to its matching syringe barrel. These micro-volume syringes have a very close tolerance between the plunger and the barrel which creates a liquid-tight seal without parts such as o-rings that eventually wear out.

Gastight Syringes

(1 µL - 100 mL delivery volume)

These syringes can be used with both liquids and gases. The precision-machined PTFE plunger tip creates a leak-free seal. The plungers are replaceable.

Step 4: Determination of the term

However, if the term does not play a role in step 3 because it is not decisive for the application, it must be selected here. For some series there is no selection and this step can be skipped. For other series, however, the selection may be large and a suitable term should be selected.

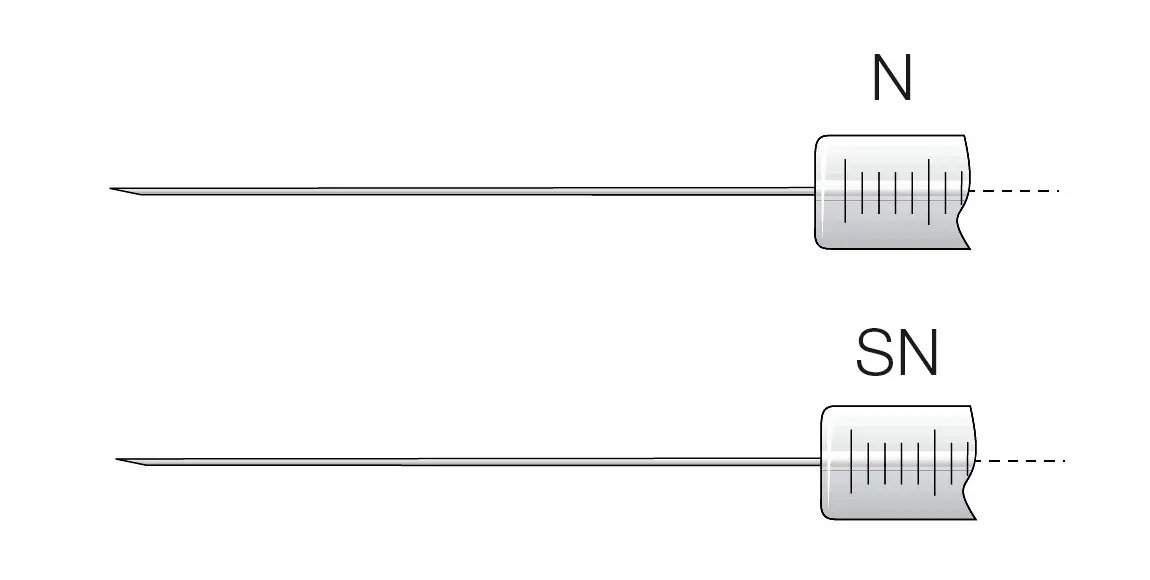

Cemented Needle (N) and Special Cemented Needle (SN)

The Cemented Needle (N) and the Special Cemented Needle (SN) are for syringes with a low volume. The needles are cemented into the glass syringe, which reduces the dead volume. However, this also means that these syringes cannot be autoclaved. With cemented needles (N), the gauge of the needle cannot be freely selected and is dependent on the volume. The Special Cemented Needle (SN) allows a choice of gauges, lengths and point styles, which means that this syringe can be customised.

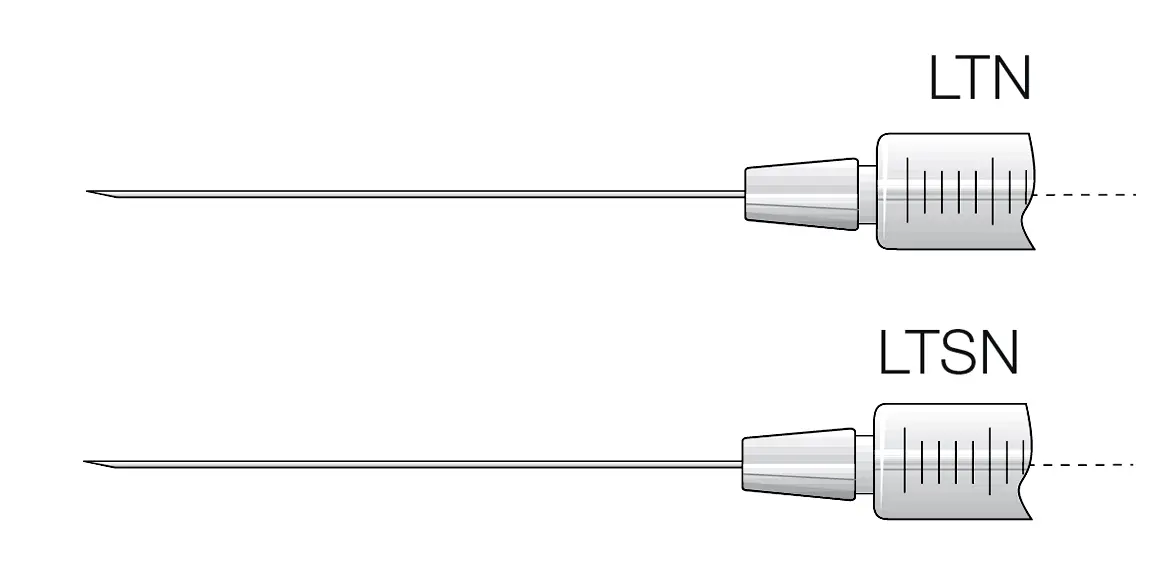

Luer Tip Cemented Needle (LTN) and Luer Tip Special Cemented Needle (LTSN)

The Luer Tip Cemented Needle (LTN) and the Luer Tip Special Cemented Needle (LTSN) are embedded in the glass syringe. This results in a low dead volume, but these syringes cannot be autoclaved. With the Luer Tip Cemented Needle (LTN), the gauge of the needle is not freely selectable and is determined by the volume of the syringe. The Luer Tip Special Cemented Needle (LTSN) allows a choice of different gauges, lengths and point styles so that it can be customised somewhat more.

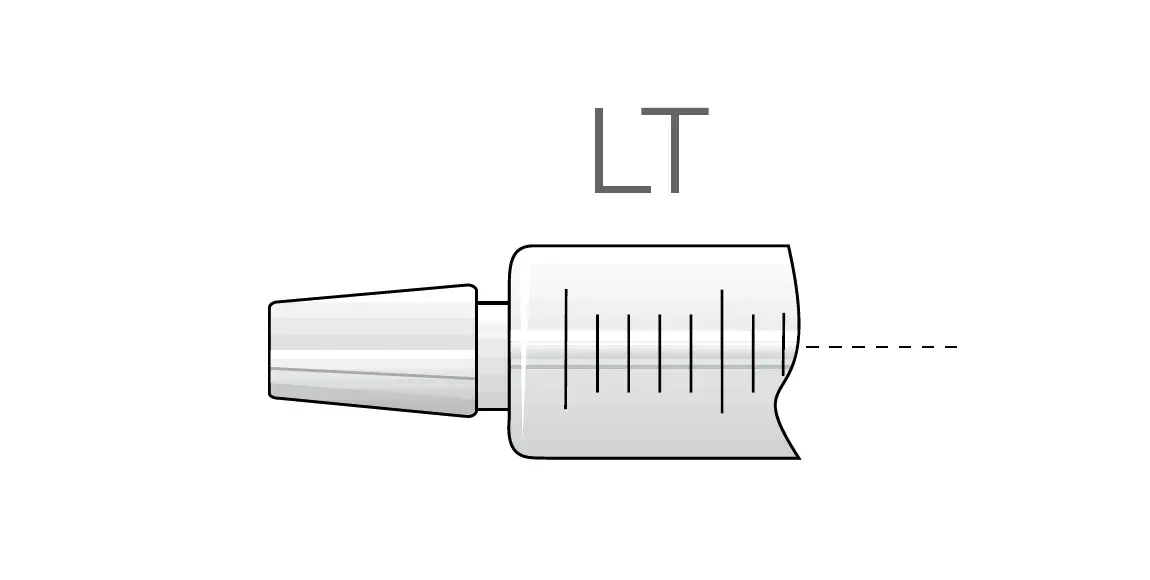

Luer Tip (LT)

The Luer Tip (LT) needles are interchangeable and the connection at the tip of the syringe is a male Luer. These luer tips are manufactured according to the ANSI standard for luer connections. This connector is compatible with most Luer hypodermic needles but is specifically designed for Kel-F needles. This connector increases the dead volume of the syringe and the syringe itself is autoclavable.

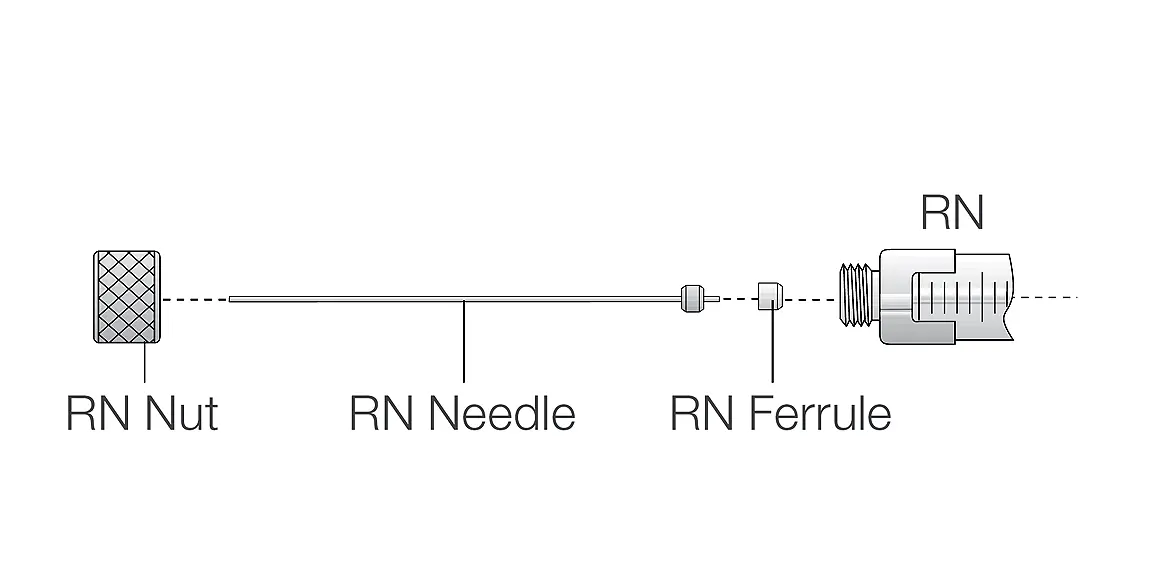

Removable Needle (RN)

The Removables Needles (RN) have a special design so that the needles sit directly on the zero graduation mark. This makes the needle interchangeable but does not increase the dead volume of the syringe. The characteristics of the needle such as gauge, length and point style can be freely selected, allowing this connection to be adapted to many requirements.

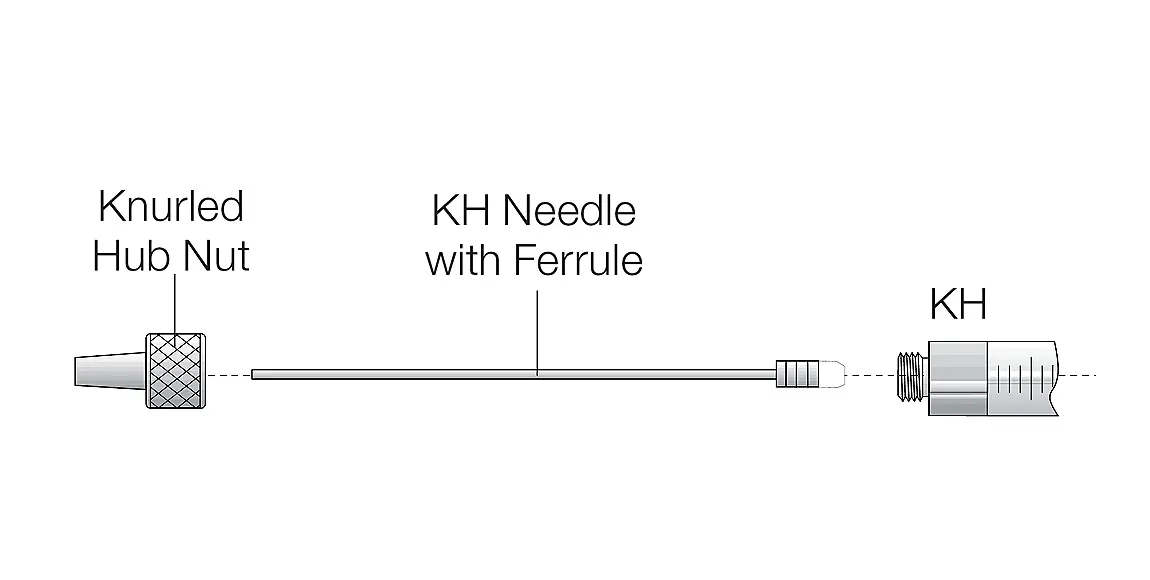

Knurled Hub (KH)

The Knurl Hub (KH) connection is only available for the 7000 series. The port can withstand an injection pressure of 6000 psig (413 bar). The needle is interchangeable but the choice of gauge is somewhat limited as the plunger fits into the needle. The removable needle makes this syringe autoclavable.

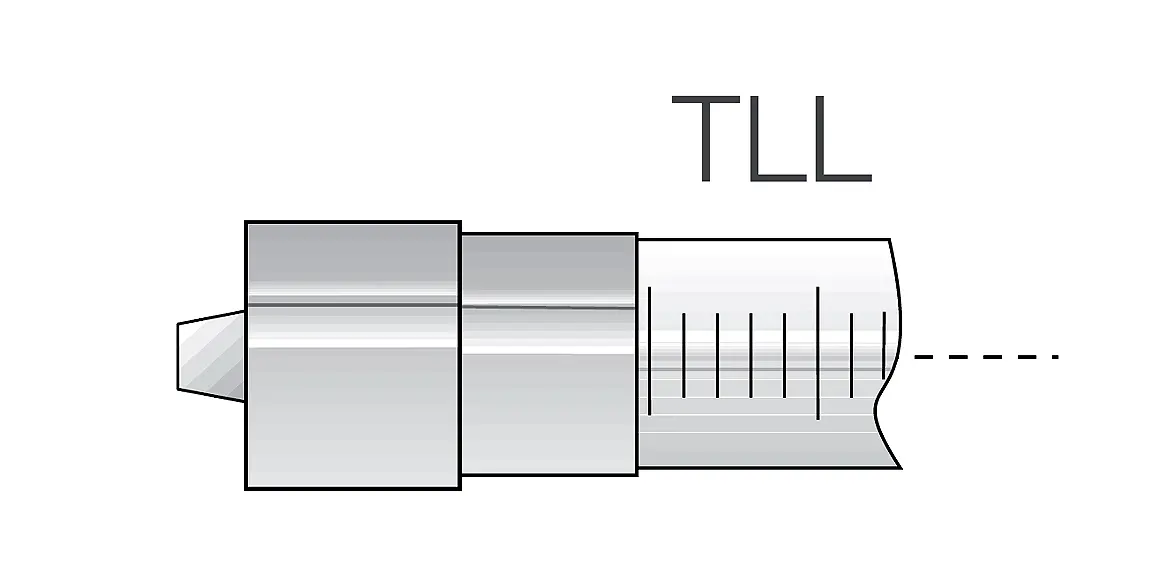

PTFE Luer Lock (TLL)

The PTFE Luer Lock (TLL) connector has a male Luer Lock PTFE cone with a nickel-plated brass screw plug. This connector can be used with Kel-F needles, metal needles and universal connectors. Due to the removable needles, these syringes are autoclavable, but not with 25 mL or larger.

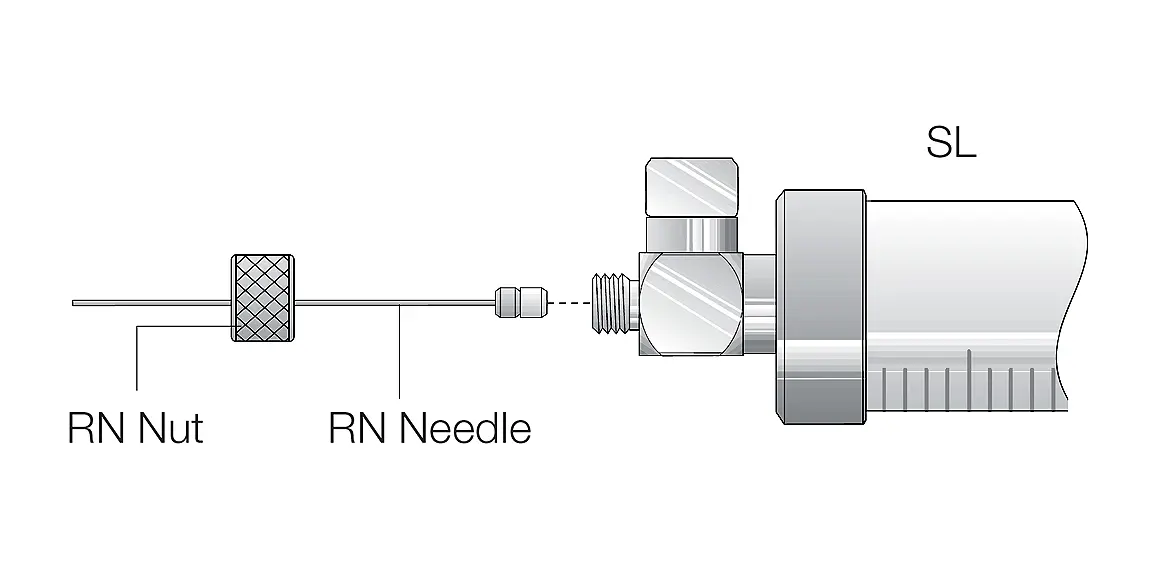

SampleLock (SL)

The SampleLock connector includes an on/off valve with a removable needle (RN). This connector is used for headspace applications, environmental sample collection and storage and for pressurised gas samples for GC. These syringes are not autoclavable.

Step 5: Selecting the needle

In the 5th step, the appropriate needle must be selected. The connection of the needle is already determined by the choice of the syringe termini. Most standard needles have a length of 51 mm and are available in different gauges and point styles. The standard gauge is 22 or 26 and the point style is usually 2 or 3. If a different gauge or point style is required, customised needles can be produced.

If you need help in choosing the right syringe, please contact us. We are happy to help with the selection!

Further information on needles and the gauge, length, connection and point style can be found on the page syringe accessories page.

Downloads

Technical support

The right column for you - we will be happy to support you individually

Competent consultants are always at your side. Write a message to our consultants, we will get back to you and give you individual support.

Hamilton Syringe Needle Reference Guide

Hamilton Syringe Needle Reference Guide

Hamiton Syringe Selection Guide

Hamiton Syringe Selection Guide