- 3% Discount on online orders

- Fast Delivery Times

- DIN ISO 9001:2015 Certified

- Manufacturer Expertise

- Contact Us

Checkout using your account

Checkout as a new customer

Creating an account has many benefits:

- See order and shipping status

- Track order history

- Check out faster

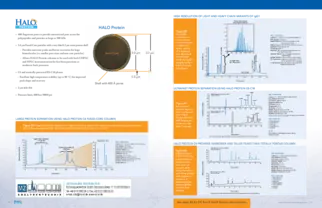

FusedCore® particle technology for fast and super-rugged HPLC-columns

Advanced Materials Technology™ is genuine developer and producer of packing materials with FusedCore® technology, bridging the gap between UHPLC and HPLC. The company Advanced Materials Technology has been created by outstanding pioneers from the field of high-performace liquid chromatography. These individuals have been responsible in the past for the invention, manufacture and product launch of Zorbax® brand columns and later founded Rockland Technologies. With their 30-plus years of experience in the chromatography world they created a new company dedicated to new innovative HPLC products.

The introduction of HALO® 2.7 micron Fused-Core® columnsin the year 2006 has revolutionised the chromatography world. HALO® columns deliver outstanding separation power (theoretical plates) comparable to UHPLC columns without the back pressure seen in sub 2 micron columns. HALO® bridges the gap between UHPLC and HPLC. AMT give customer webinars on demand, please contact us for further information!

Products

Technical Data

What are the advantages of fused-core technology?

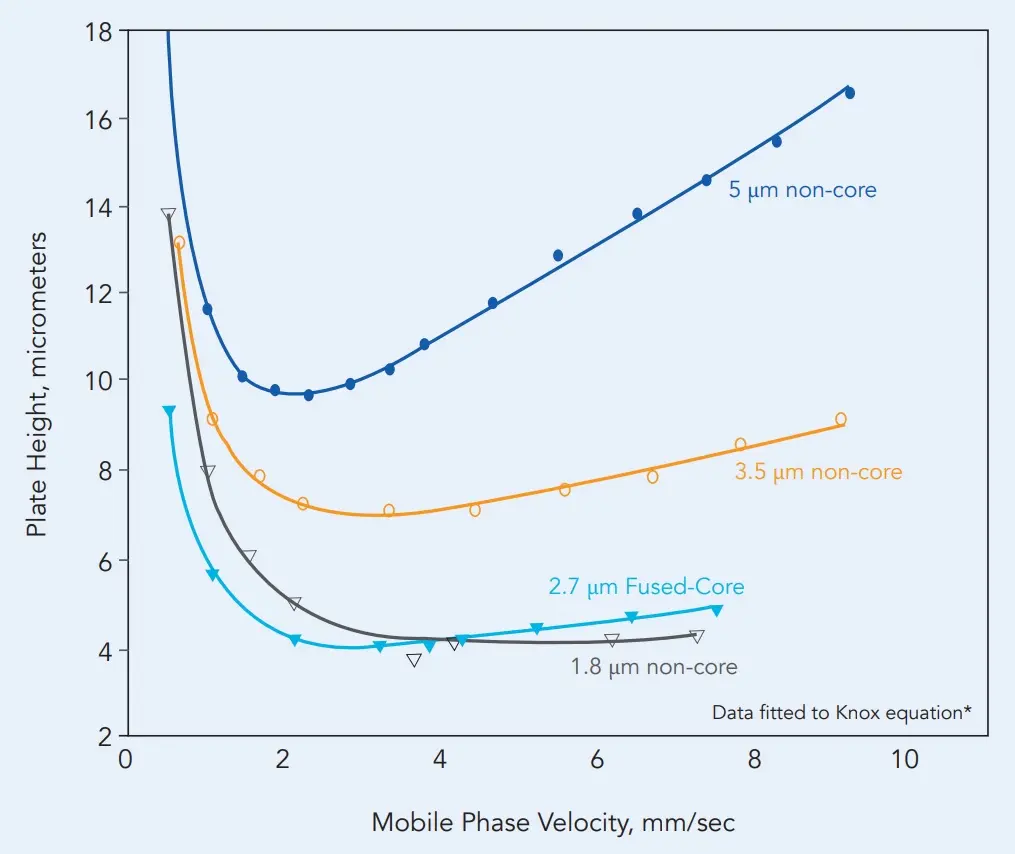

In fused-core technology (or core-shell, superficially porous particles SPP), the particles consist of a non-porous core and a porous shell. This thin, porous shell enables faster mass transfer of the analytes between the mobile and stationary phases. This reduces the broadening of peaks due to mass transfer and therefore the B term of the van Deemter equation is smaller compared to fully porous particles. With fused-core technology, more uniform particles are also obtained, resulting in a more uniform flow through the packing bed. This in turn reduces the A-term of the van Deemter equation.

The reduction in the A-term and B-term results in significantly lower theoretical plate heights and therefore higher efficiencies (higher plate counts) of core-shell particles. This means that higher flow rates are possible with the same efficiency. Thus, a 2.7µm particle with fused-core technology has a similar separation performance as a sub 2µm fully porous material. Due to the non-porous core, the back pressure is as low as with 5µm particles, so that a UHPLC-like performance can be achieved on a conventional HPLC.

Downloads

Brochures

-

AMT DANDY VICE Instructions-for-use Brochure

AMT DANDY VICE Instructions-for-use Brochure

-

HPLC UHPLC Fused-Core

AMT HALO 1.5mm Column Fused Core UHPLC Columns Brochure

AMT HALO 1.5mm Column Fused Core UHPLC Columns Brochure

-

AMT HALO 2 ES C18 Peptide Column Brochure

AMT HALO 2 ES C18 Peptide Column Brochure

-

HPLC Fused-Core

AMT HALO 5 Fused Core HPLC Columns Brochure

AMT HALO 5 Fused Core HPLC Columns Brochure

-

AMT HALO® C18 Isocratic Separation on Aflatoxins Brochure

AMT HALO® C18 Isocratic Separation on Aflatoxins Brochure

-

AMT HALO C30 Columns Brochure

AMT HALO C30 Columns Brochure

-

AMT HALO Elevate C18 Brochure

AMT HALO Elevate C18 Brochure

-

AMT HALO OLIGO C18 Brochure

AMT HALO OLIGO C18 Brochure

-

AMT HALO PCS-C18 Brochure

AMT HALO PCS-C18 Brochure

-

HPLC

AMT HALO® PCS-Family HPLC Brochure

AMT HALO® PCS-Family HPLC Brochure

-

AMT HALO 90Å C18, AQ-C18, Biphenyl, New Alternatives to C18 Brochure

AMT HALO 90Å C18, AQ-C18, Biphenyl, New Alternatives to C18 Brochure

-

AMT Enhanced Selectivity With the HALO 160Å Phenyl-Hexyl Column Brochure

AMT Enhanced Selectivity With the HALO 160Å Phenyl-Hexyl Column Brochure

-

AMT HALO Bioclass Protein 400Å Diphenyl Brochure

AMT HALO Bioclass Protein 400Å Diphenyl Brochure

-

AMT HALO 1000Å C4 Protein Column for High Resolution Separation of a Monoclonal Antibody

AMT HALO 1000Å C4 Protein Column for High Resolution Separation of a Monoclonal Antibody

-

AMT HALO 1000Å Diphenyl Brochure

AMT HALO 1000Å Diphenyl Brochure

-

AMT HALO® 1000Å Diphenyl Brochure

AMT HALO® 1000Å Diphenyl Brochure

-

AMT HALO® Applications Collection Brochure

AMT HALO® Applications Collection Brochure

-

AMT HALO AQ-C18 Columns Brochure

AMT HALO AQ-C18 Columns Brochure

-

AMT HALO Bioclass 1000Å Protein Selectivity Kit Biotherapeutic Method Development Guide

AMT HALO Bioclass 1000Å Protein Selectivity Kit Biotherapeutic Method Development Guide

-

AMT HALO Bioclass Fused-Core Columns Brochure 2018

AMT HALO Bioclass Fused-Core Columns Brochure 2018

-

HPLC

AMT HALO Bioclass Brochure

AMT HALO Bioclass Brochure

-

AMT HALO Biphenyl Brochure

AMT HALO Biphenyl Brochure

-

AMT HALO® Catalog

AMT HALO® Catalog

-

HPLC UHPLC

AMT HALO® Catalog 2023

AMT HALO® Catalog 2023

-

AMT HALO Introducing HALO PFAS Column Solutions

AMT HALO Introducing HALO PFAS Column Solutions

-

AMT HALO Enviroclass - HALO-PFAS Environmental Analysis

AMT HALO Enviroclass - HALO-PFAS Environmental Analysis

-

HPLC UHPLC

AMT HALO Peptide ES-C18 UHPLC Columns Separation of Peptides Brochure

AMT HALO Peptide ES-C18 UHPLC Columns Separation of Peptides Brochure

-

Fused-Core

AMT HALO Fused-Core Technology Brochure

AMT HALO Fused-Core Technology Brochure

-

HPLC Fused-Core

AMT HALO Fused-Core HPLC Columns Product Bulletin Brochure

AMT HALO Fused-Core HPLC Columns Product Bulletin Brochure

-

Fused-Core

AMT HALO2 FusedCore columns

AMT HALO2 FusedCore columns

-

AMT, HALO, LPH - C18 Columns

AMT, HALO, LPH - C18 Columns

-

AMT HALO Method Development Kit Promotion Brochure

AMT HALO Method Development Kit Promotion Brochure

-

AMT HALO Introducing HALO PAH Columns Brochure

AMT HALO Introducing HALO PAH Columns Brochure

-

AMT HALO PFAS PAH Pesticides Enviromental Analysis Brochure

AMT HALO PFAS PAH Pesticides Enviromental Analysis Brochure

-

HPLC UHPLC

AMT HALO PFP UHPLC Columns Brochure

AMT HALO PFP UHPLC Columns Brochure

-

HPLC UHPLC

AMT HALO Phenyl Hexyl UHPLC Columns Brochure

AMT HALO Phenyl Hexyl UHPLC Columns Brochure

-

HPLC UHPLC

AMT HALO RP Amide C8 C18 UHPLC Columns Alternate Complementary Selectivity Brochure

AMT HALO RP Amide C8 C18 UHPLC Columns Alternate Complementary Selectivity Brochure

Applications

-

AMT HALO 1.5mm Column 90Å C18 Sensitivity Solvent Savings with Cannabinoids Application

AMT HALO 1.5mm Column 90Å C18 Sensitivity Solvent Savings with Cannabinoids Application

-

AMT HALO 1.5mm-Column 90Å C18 Alkylphenones Application

AMT HALO 1.5mm-Column 90Å C18 Alkylphenones Application

-

AMT HALO 1.5mm Column 90Å C18 Small Molecule Cough And Cold Meds Application

AMT HALO 1.5mm Column 90Å C18 Small Molecule Cough And Cold Meds Application

-

AMT HALO 1.5mm Column 160Å ES C18 Trastuzumab Tryptic Digest Application

AMT HALO 1.5mm Column 160Å ES C18 Trastuzumab Tryptic Digest Application

-

AMT HALO 1.5mm Column 1000Å Diphenyl Intact Trastuzumab Application

AMT HALO 1.5mm Column 1000Å Diphenyl Intact Trastuzumab Application

-

AMT HALO 1.5mm Column 1000Å Diphenyl Reduced Trastuzumab Application

AMT HALO 1.5mm Column 1000Å Diphenyl Reduced Trastuzumab Application

-

AMT HALO 1.5mm Column 1000Å C4 Sensitivity Increase of Mixed Proteins Application

AMT HALO 1.5mm Column 1000Å C4 Sensitivity Increase of Mixed Proteins Application

-

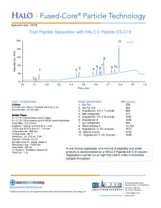

AMT HALO Fast Peptide Separation with HALO 2 Peptide ES-C18 Application

AMT HALO Fast Peptide Separation with HALO 2 Peptide ES-C18 Application

-

AMT HALO 2 ES C18 Peptide High Temperature Low pH Stability Application

AMT HALO 2 ES C18 Peptide High Temperature Low pH Stability Application

-

AMT HALO 2 ES C18 Peptide Peak Capacity Application

AMT HALO 2 ES C18 Peptide Peak Capacity Application

-

AMT HALO 5 C18 Determination of Caffeine in Soda Application

AMT HALO 5 C18 Determination of Caffeine in Soda Application

-

AMT HALO 90Å Biphenyl LC MS Separation of Fentanyl & Analogues in Synthetic Urine Application

AMT HALO 90Å Biphenyl LC MS Separation of Fentanyl & Analogues in Synthetic Urine Application

-

HPLC

AMT Fast Separation of Ten Cannabinoids on HALO C18

AMT Fast Separation of Ten Cannabinoids on HALO C18

-

HPLC

AMT Separation of 14 Cannabinoids on HALO C18

AMT Separation of 14 Cannabinoids on HALO C18

-

AMT Isocratic Separation of 18 Cannabinoids

AMT Isocratic Separation of 18 Cannabinoids

-

AMT HALO Glycan Separation of Amino Acids by HILIC/MS

AMT HALO Glycan Separation of Amino Acids by HILIC/MS

-

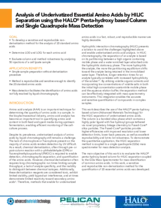

AMT HALO Glycan Analysis of Underivatized Essential Amino Acids by HILIC/MS

AMT HALO Glycan Analysis of Underivatized Essential Amino Acids by HILIC/MS

-

AMT HALO 90Å LPH C18 Pesticide Screening of Barley Application

AMT HALO 90Å LPH C18 Pesticide Screening of Barley Application

-

AMT HALO AQ-C18 & HALO Penta-HILIC Amino Acid Analysis in Biological Matrices

AMT HALO AQ-C18 & HALO Penta-HILIC Amino Acid Analysis in Biological Matrices

-

AMT HALO C18 2.7um Separation of 6 Flavonoids Application

AMT HALO C18 2.7um Separation of 6 Flavonoids Application

-

AMT HALO C18 HPLC Analysis of Chlorogenic Acid in Coffee Extract Application

AMT HALO C18 HPLC Analysis of Chlorogenic Acid in Coffee Extract Application

-

AMT HALO C18 Separation of Steroid Hormones & Hormone Conjugates Application

AMT HALO C18 Separation of Steroid Hormones & Hormone Conjugates Application

-

AMT HALO Elevate C18 Amitriptyline Stability Test Applications

AMT HALO Elevate C18 Amitriptyline Stability Test Applications

-

AMT HALO Elevate C18 Nicotine Analysis Application

AMT HALO Elevate C18 Nicotine Analysis Application

-

AMT HALO Elevate C18 Omeprazole Analysis Application

AMT HALO Elevate C18 Omeprazole Analysis Application

-

AMT HALO Elevate C18 Separation of Antidepressants Applications

AMT HALO Elevate C18 Separation of Antidepressants Applications

-

AMT-HALO® Separation of Procainamide-Labeled Dextran Standards

AMT-HALO® Separation of Procainamide-Labeled Dextran Standards

-

AMT-HALO® Separation of PNGase-Released & Labeled N-Glycans

AMT-HALO® Separation of PNGase-Released & Labeled N-Glycans

-

AMT Advantages of HALO OLIGO C18

AMT Advantages of HALO OLIGO C18

-

AMT HALO OLIGO C18 Separation of Oligonucleotide Ladder via LC/MS

AMT HALO OLIGO C18 Separation of Oligonucleotide Ladder via LC/MS

-

AMT HALO OLIGO C18 Oligonucleotide Performance Mix

AMT HALO OLIGO C18 Oligonucleotide Performance Mix

-

AMT HALO OLIGO C18 Oligonucleotide Ladder via UV Detection

AMT HALO OLIGO C18 Oligonucleotide Ladder via UV Detection

-

AMT HALO OLIGO C18 Lot-to-Lot Reproducibility

AMT HALO OLIGO C18 Lot-to-Lot Reproducibility

-

AMT HALO PFAS EPA Method 1633 for PFAS

AMT HALO PFAS EPA Method 1633 for PFAS

-

AMT HALO Comparison on 1000Å C4, ES-C18, Diphenyl

AMT HALO Comparison on 1000Å C4, ES-C18, Diphenyl

-

AMT-HALO® Analysis of PFAS in Well Water Spiked with Standards

AMT-HALO® Analysis of PFAS in Well Water Spiked with Standards

-

Standards

AMT HALO Analysis of PFAS in Well Water Spiked with Standards Application

AMT HALO Analysis of PFAS in Well Water Spiked with Standards Application

-

AMT HALO Analysis of proteins

AMT HALO Analysis of proteins

-

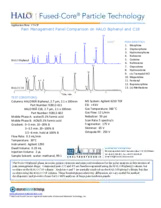

AMT HALO Pain Management Panel Comparison on HALO Biphenyl and C18

AMT HALO Pain Management Panel Comparison on HALO Biphenyl and C18

-

AMT HALO C18 Separation of Neonicotinoids

AMT HALO C18 Separation of Neonicotinoids

-

AMT-HALO® Demonstration of the HALO® PFAS Delay Column

AMT-HALO® Demonstration of the HALO® PFAS Delay Column

-

AMT HALO Food & Beverage LC-MS Separation of Common Catechins Found in Tea

AMT HALO Food & Beverage LC-MS Separation of Common Catechins Found in Tea

-

AMT HALO Pharmaceuticals Low pH Stability with HALO LPH-C18 Columns

AMT HALO Pharmaceuticals Low pH Stability with HALO LPH-C18 Columns

-

AMT HALO® PAH App-Note_18-PAH-HALO®, PAH-3x100

AMT HALO® PAH App-Note_18-PAH-HALO®, PAH-3x100

-

AMT HALO® PAH App-Note EPA 610-2-under-5min

AMT HALO® PAH App-Note EPA 610-2-under-5min

-

AMT HALO® App-Note PAH-vs-FPP

AMT HALO® App-Note PAH-vs-FPP

-

AMT HALO Penta-HILIC Separation of Nucleotides

AMT HALO Penta-HILIC Separation of Nucleotides

-

AMT-HALO® PFAS Analysis According to EPA 533

AMT-HALO® PFAS Analysis According to EPA 533

-

AMT-HALO® PFAS Analysis According to EPA 537.1 Using HALO® 90 Å C18, 2.0 μm

AMT-HALO® PFAS Analysis According to EPA 537.1 Using HALO® 90 Å C18, 2.0 μm

-

AMT-HALO® PFAS Analysis According to EPA 537.1

AMT-HALO® PFAS Analysis According to EPA 537.1

-

AMT-HALO® PFAS Analysis According to EPA 8327

AMT-HALO® PFAS Analysis According to EPA 8327

-

AMT HALO Environmental PFAS Analysis According to EPA 533 Application

AMT HALO Environmental PFAS Analysis According to EPA 533 Application

-

AMT HALO PFAS Analysis According to EPA 537.1 Application

AMT HALO PFAS Analysis According to EPA 537.1 Application

-

AMT HALO PFAS Analysis According to EPA 8327 Application

AMT HALO PFAS Analysis According to EPA 8327 Application

-

AMT HALO Phenyl Hexyl & RP Amide Phases Separation of Food Additives Application

AMT HALO Phenyl Hexyl & RP Amide Phases Separation of Food Additives Application

-

AMT HALO Phenyl Hexyl Separation Of Penicillins Application

AMT HALO Phenyl Hexyl Separation Of Penicillins Application

-

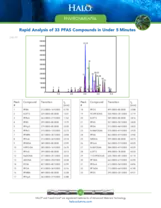

AMT-HALO® Rapid Analysis of 33 PFAS Compounds in Under 5 Minutes

AMT-HALO® Rapid Analysis of 33 PFAS Compounds in Under 5 Minutes

-

AMT-HALO® Rapid PFAS Analysis According to EPA 537.1 using HALO® 90 Å Phenyl-Hexyl, 2.7 μm Peak

AMT-HALO® Rapid PFAS Analysis According to EPA 537.1 using HALO® 90 Å Phenyl-Hexyl, 2.7 μm Peak

-

AMT HALO RP Amide Separation of Amoxicillin & Ampicillin Application

AMT HALO RP Amide Separation of Amoxicillin & Ampicillin Application

-

AMT HALO Separation of 18 Cannabinoids Using HALO LPH-C18 Application

AMT HALO Separation of 18 Cannabinoids Using HALO LPH-C18 Application

-

AMT HALO® Separation-of-Aflatoxins

AMT HALO® Separation-of-Aflatoxins

-

AMT HALO Separation of Anthocyanins in Blueberries Application

AMT HALO Separation of Anthocyanins in Blueberries Application

-

AMT HALO Separation of Common Catechins & Caffeine Found in Tea via LC-UV Application

AMT HALO Separation of Common Catechins & Caffeine Found in Tea via LC-UV Application

-

AMT HALO Separation of Polyphenols in Wine Application

AMT HALO Separation of Polyphenols in Wine Application

-

AMT HALO MZ-Apps HALO-Glycan Information Sheet

AMT HALO MZ-Apps HALO-Glycan Information Sheet

-

AMT HALO 2 MZ-Apps Peptides & Proteins ES-C18 Lot Reproducibility Application

AMT HALO 2 MZ-Apps Peptides & Proteins ES-C18 Lot Reproducibility Application

-

AMT HALO MZ-Apps Rp HALO 400Å C4 Protein Columns

AMT HALO MZ-Apps Rp HALO 400Å C4 Protein Columns

-

AMT HALO MZ-Apps Rp HALO 1000Å Brochure

AMT HALO MZ-Apps Rp HALO 1000Å Brochure

-

AMT HALO MZ-Apps Rp Halo 1000Å C4 High Resolution Separation of a Monoclonal Antibody Application

AMT HALO MZ-Apps Rp Halo 1000Å C4 High Resolution Separation of a Monoclonal Antibody Application

-

AMT HALO MZ-Apps Rapid Separation of Vitamin E Congeners on HALO PFP Application

AMT HALO MZ-Apps Rapid Separation of Vitamin E Congeners on HALO PFP Application

-

AMT HALO MZ-Apps Separation Of Water Soluble Vitamins Application

AMT HALO MZ-Apps Separation Of Water Soluble Vitamins Application

Technical Support

-

SPE

AMT HALO 1.5mm Column 90Å C18 Microflow Extracolumn Dispersion Technical Support

AMT HALO 1.5mm Column 90Å C18 Microflow Extracolumn Dispersion Technical Support

-

AMT HALO 1.5mm Column 160Å ES C18 1000Å Diphenyl Top-Down & Bottom-Up Technical Support

AMT HALO 1.5mm Column 160Å ES C18 1000Å Diphenyl Top-Down & Bottom-Up Technical Support

-

AMT HALO C30 Columns Technical Support

AMT HALO C30 Columns Technical Support

-

Fused-Core

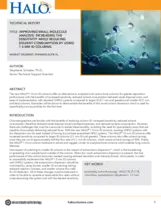

AMT HALO Rapid & High Resolution Fused-Core Solutions for PFAS Analysis

AMT HALO Rapid & High Resolution Fused-Core Solutions for PFAS Analysis

-

AMT HALO Bioanalysis Solutions Guidebook

AMT HALO Bioanalysis Solutions Guidebook

-

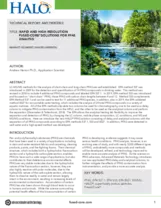

AMT HALO Cannabinoid Separations and the Impact of LC Column Selectivity

AMT HALO Cannabinoid Separations and the Impact of LC Column Selectivity

-

AMT HALO Method Conversion Guidebook

AMT HALO Method Conversion Guidebook

-

AMT HALO®-PAH Small-Molecule

AMT HALO®-PAH Small-Molecule

-

AMT HALO Toss-Sheet on High Resolution Separation of 18 PAH Compounds

AMT HALO Toss-Sheet on High Resolution Separation of 18 PAH Compounds

-

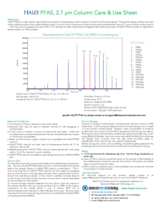

AMT HALO PFAS, 2.7 μm Column Care & Use Sheet Application

AMT HALO PFAS, 2.7 μm Column Care & Use Sheet Application

-

AMT HALO PFAS Delay, 2.7 μm Column Care & Use Sheet

AMT HALO PFAS Delay, 2.7 μm Column Care & Use Sheet

-

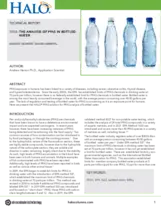

AMT-HALO PFAS in Bottled Water Technical Support

AMT-HALO PFAS in Bottled Water Technical Support

-

HPLC

AMT HALO RP Chemistries Utilizing Selectivity for HPLC Separations Technical Support

AMT HALO RP Chemistries Utilizing Selectivity for HPLC Separations Technical Support

The right column for you - we will be happy to support you individually

Competent consultants are always at your side. Write a message to our consultants, we will get back to you and give you individual support.